ICD/ITKE – RESEARCH PAVILION

2011

Institute for Computational Design (ICD) –

Prof. Achim Menges

Institute of Building Structures and Structural Design (ITKE) –

Prof. Dr.-Ing. Jan Knippers

In the summer 2011 the Institute for Computational Design (ICD) and the Institute of Building Structures and Structural Design (ITKE), together with the students at the University of Stuttgart have realized a temporary research pavilion. The project explored the transfer to architecture of biological principles of the sea urchin’s plate skeleton morphology. This was achieved by means of novel computer-based design and simulation methods, along with computer-controlled manufacturing methods.

Biological Model

The project aimed at integrating the performative qualities of biological structures into architectural design and at testing these results on a spatial and structural material-system. During the analysis of biological structures, the morphology of the sand dollar’s skeleton, a sub-species of the sea urchin (Echinoidea), was of particular interest, which provided the basic principles of the bionic structure that was realized. The shell of the sand dollar consists of a modular system of polygonal plates, which are linked together at the edges by finger-like calcite protrusions. High load bearing capacity is achieved by the particular geometric arrangement of the plates and their joining system. Therefore, the sand dollar serves as a perfect model for shells made of prefabricated elements. Similarly, the finger-joints typically used in carpentry as connection elements, may be seen as the equivalent of the sand dollar’s calcite protrusions.

Morphology Transfer

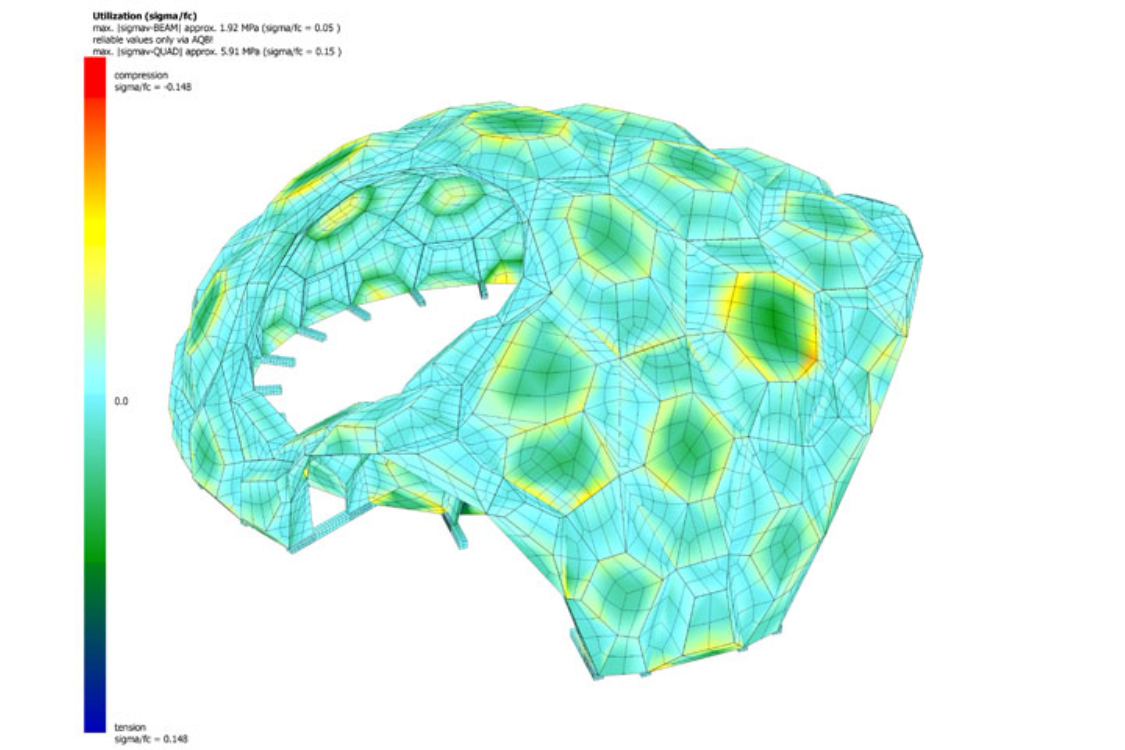

Following the analysis of the sand dollar, the morphology of its plate structure was translated into the design of a pavilion. Three plate edges always meet together at just one point, a principle which enables the transmission of normal and shear forces but no bending moments between the joints, thus resulting in a bending bearing but yet deformable structure. Unlike traditional lightweight construction, which can only be applied to load optimized shapes, this new design principle can be applied to any custom geometry. The high lightweight potential of this approach is evident as the pavilion, despite its considerable size, could be built out of 6.5 mm thin sheets of plywood, which resulted in a great material saving.

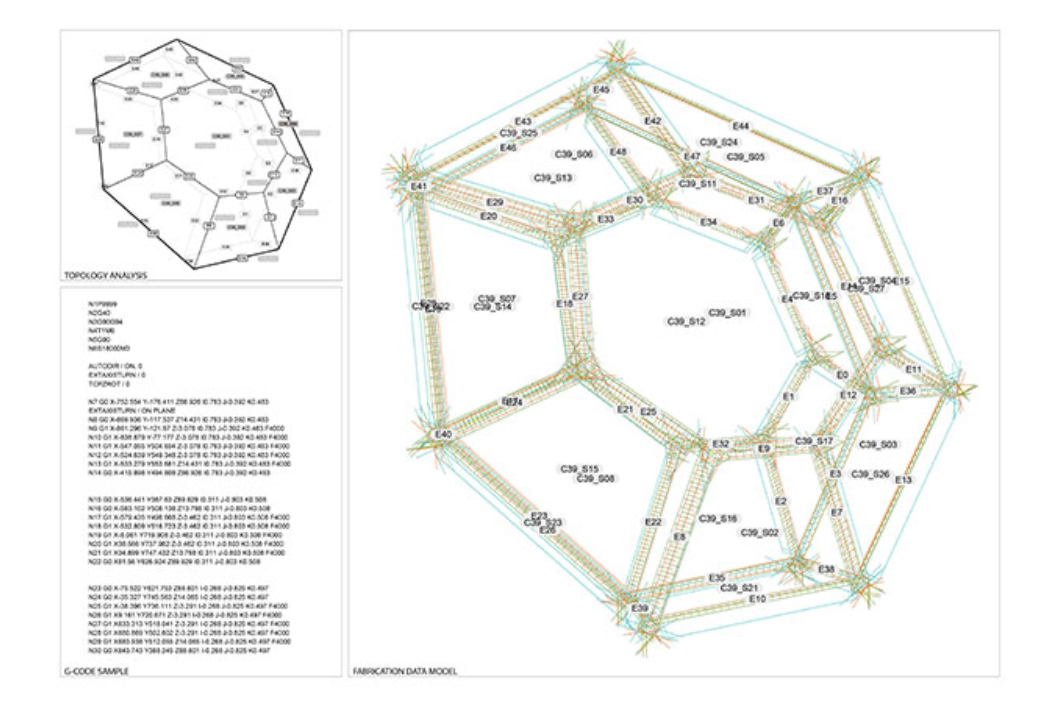

Digital Design and Robotic Production

The plates of each cell were finally produced with the university‘s robotic fabrication system. Using custom scripting routines the digital building model provided the basis for the automatic generation of the machine code for the control of the industrial robot. This enabled the economical production of more than 850 geometrically different components, as well as more than 100,000 finger joints freely arranged in space. Following the robotic production, the plywood panels were joined together to form the cells, which were successively primed and stained. The assembly of the prefabricated modules was carried out continuously at the downtown campus of the University of Stuttgart. Both the structural analysis, NC programming and the development were carried out jointly by the students and faculty members.

Images © ICD/ITKE

PROJECT TEAM

Institute for Computational Design (ICD)

Prof. Achim Menges

Institute of Building Structures and Structural Design (ITKE) –

Prof. Dr.-Ing. Jan Knippers

CONCEPT & PROJECT DEVELOPMENT

Oliver David Krieg,

Boyan Mihaylov

PLANNING & REALIZATION

Peter Brachat, Benjamin Busch, Solmaz Fahimian,

Christin Gegenheimer, Nicola Haberbosch,

Elias Kästle, Oliver David Krieg, Yong Sung Kwon,

Boyan Mihaylov, Hongmei Zhai

SCIENTIFIC DEVELOPMENT

Markus Gabler (project management),

Riccardo La Magna (structural design),

Steffen Reichert (detailing),

Tobias Schwinn (project management),

Frédéric Waimer (structural design)